Aluminum foam for building material

Classification:

Key words:

Product

Hotline:

+86 0757-87653135

Product Description

Graphic Details

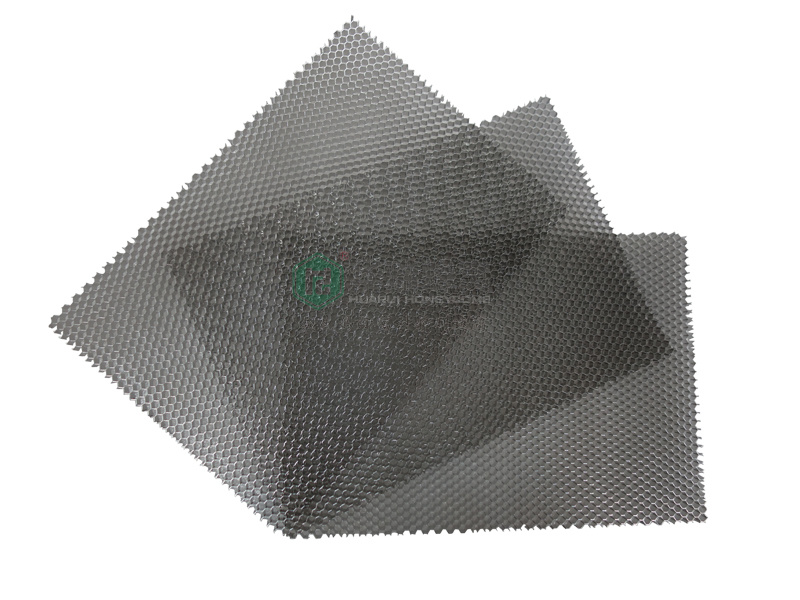

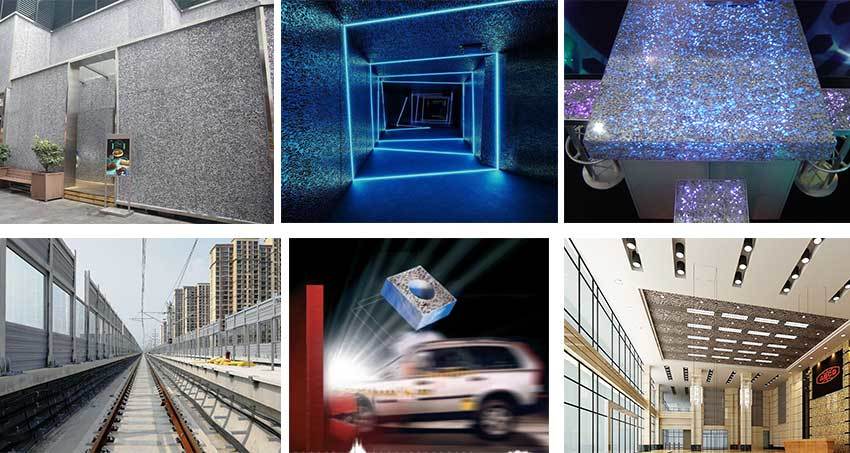

Aluminum foam board has excellent physical properties, chemical properties, mechanical properties and recyclability; aluminum foam "sandwich" composite board structure is characterized by light weight and high rigidity, and can be used as an excellent structural material. The products are aluminum foam boards and aluminum foam composite boards, which have the characteristics of ultra-light weight, sound absorption and noise reduction, energy absorption, high temperature resistance, non-aging, etc., and are widely used in rail transit, vehicles, building decoration, home decoration and sound insulation.

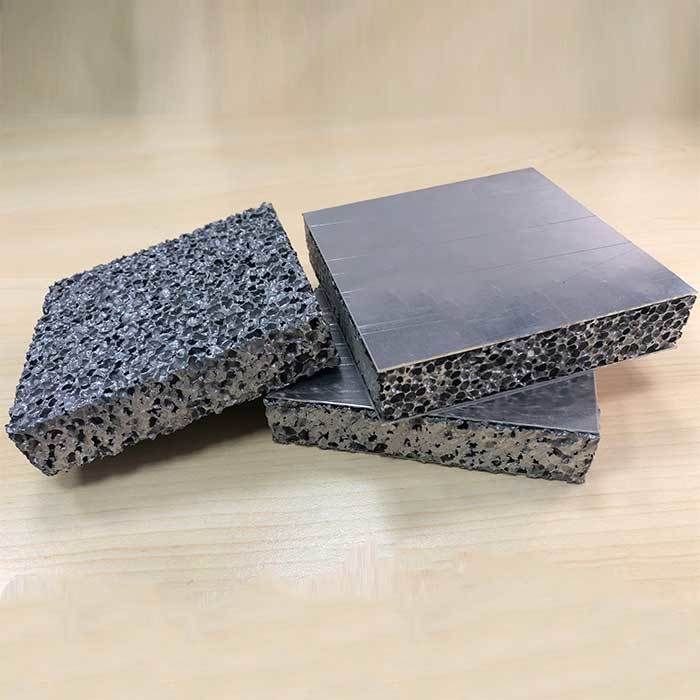

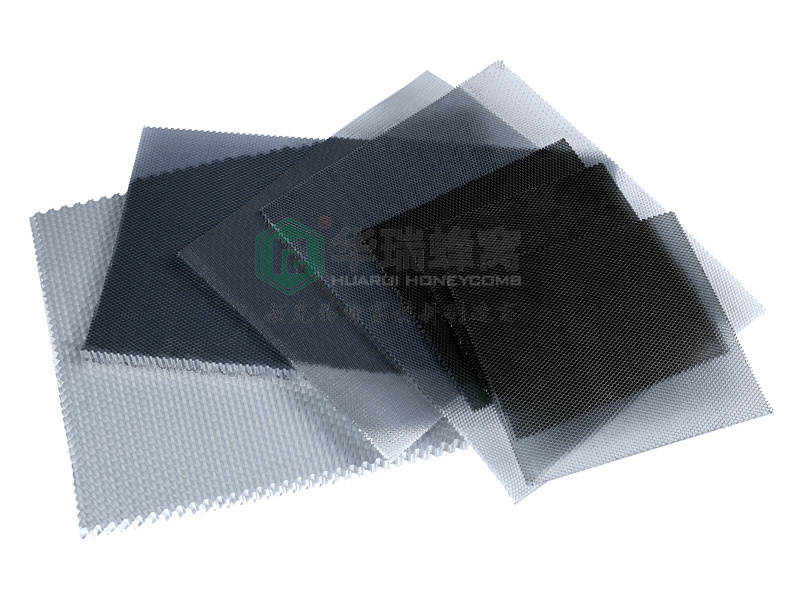

Aluminum Foam

Aluminum foam is made by adding additives to pure aluminum or aluminum alloy and undergoing a foaming process, which has both metal and bubble characteristics. Aluminum foam has excellent performance characteristics as follow.

Corrosion resistance

There is no obvious abnormality after being exposed to the marine atmospheric environment for one year; under accelerated corrosion conditions, there is no abnormality in the water spray and salt spray test for 2 years; it shows that the corrosion resistance of foamed aluminum is very good. The surface can be sprayed with anti-corrosion treatment to further improve the anti-corrosion ability.

Non-hygroscopic

The moisture absorption rate of aluminum foam is 0.0%. There is no moisture absorption and no degradation of acoustic performance due to moisture.

Heat-resistant/non-combustible properties

Tested by the National Fireproof Building Materials Quality Supervision and Inspection Center, the combustion performance reaches A1 level.

Thermal insulation performance

The thermal conductivity of foamed aluminum is 0.25~0.62W/m-K, which is equivalent to that of marble, and has good thermal insulation performance and thermal stability. The linear expansion coefficient of foamed aluminum is 19.34*10/C, which is equivalent to that of concrete, and it is not easy to deform when heated.

Green and environmental friendly

Aluminum foam is a composite material composed of metal and pores. It is non-toxic and will not release toxic gases at high temperatures. Recyclable: The main chemical composition of aluminum foam is aluminum alloy and its oxides, which can be 100% recycled and reused. any pollution to the environment.

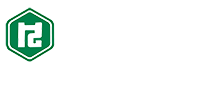

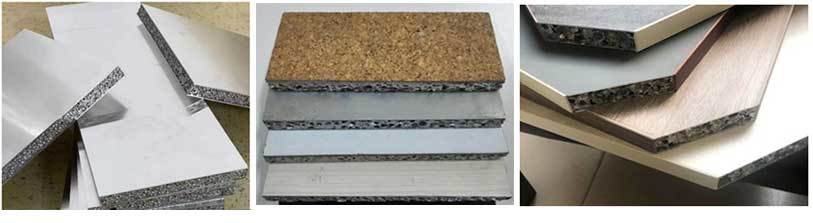

Aluminum foam sandwich

It can be single-sided/double-sided composited with metal (aluminum plate, steel plate, etc.) and non-metallic (wooden, marble, glass fiber, carbon fiber, rubber, PE, etc.) materials according to requirements. The aluminum foam material is used as the base material, which can be laminated on one or both sides, and the layers are bonded by high temperature hot pressing or room temperature. It has light weight, high specific stiffness, aging resistance, good energy absorption, impact resistance, fire and explosion protection, etc.

Application

Widely used in indoor and outdoor decoration (decoration) materials, heat and sound insulation walls and fire and explosion-proof doors, energy-saving buildings, furniture, boxes, etc.; road sound barriers, ships, high-speed rail, train equipment, car structure and engine room sound insulation panels, etc.

Product Consulting

Business contact: Zhuang Sheng13501455383Miss Wang13827769412

Huarui Service Phone:0757-87653135

Enterprise E-mail:

Company Address:

Block 7, No.5, Lequn Avenue, Liping Town, Sanshui District, Foshan City